Product List

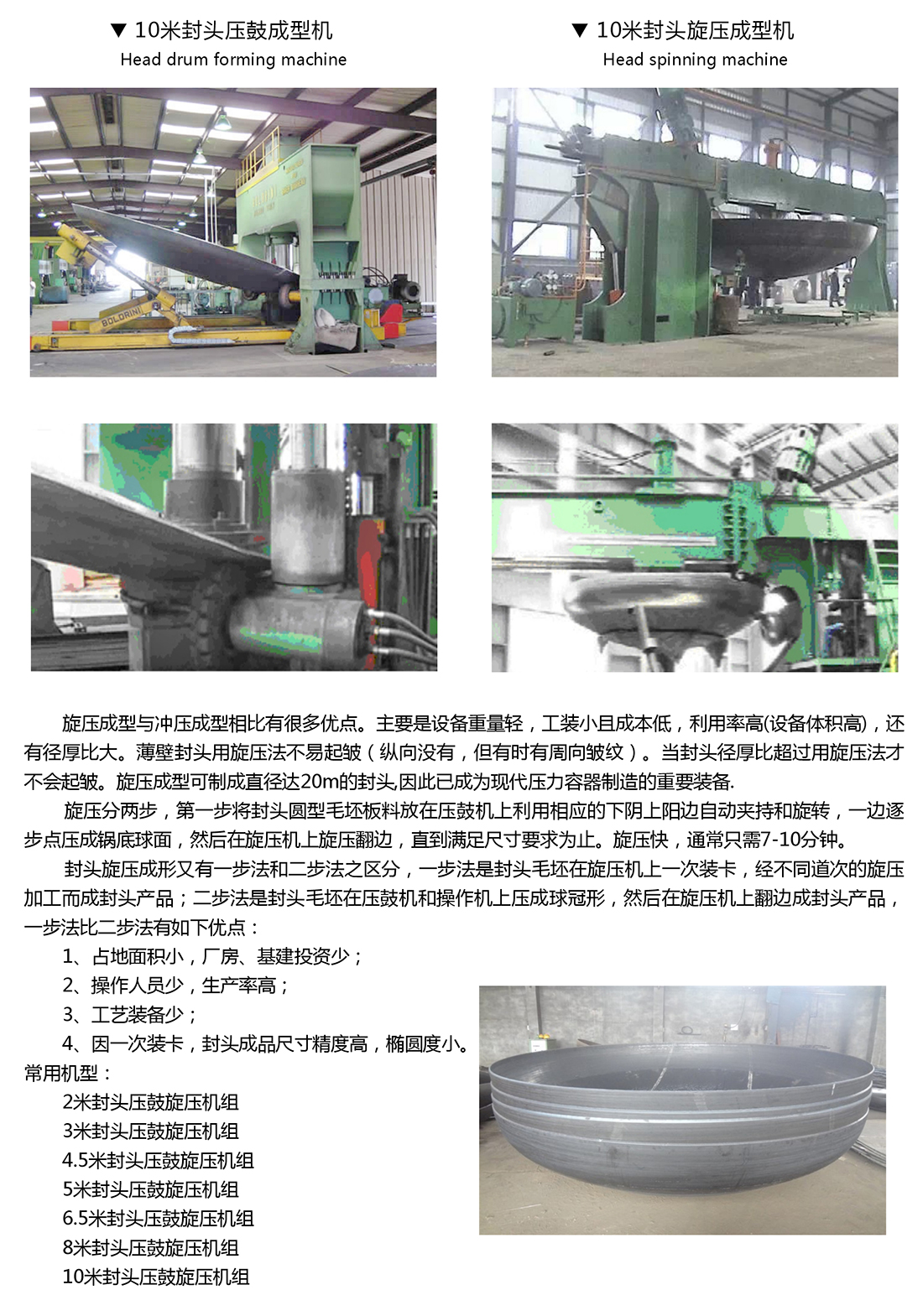

Sheet Stretching 10m Head Spinning Forming Machine

Head Spinning Forming Machine

development path:

Continuous progress should be made in spinning machine equipment, adjust the stability of the mechanical system, the advanced nature of the control and detection system, and develop towards the direction of large-scale, serial, high-precision, multi-purpose, multi-function and automation, and continue to develop new ones Spinning products, expand the application field of spinning technology, develop new spinning equipment, increase the automation of equipment and industrial production lines, and focus on the development of complex curved bus bars, different centers and combined new products, in a variety of materials composite spinning Intensify efforts in the theory and experimental research of spinning deformation mechanism theory and experimental research with multiple manufacturing methods based on spinning and spinning, and forming a more comprehensive, systematic and reliable spinning machine basic theory and quality control system as soon as possible. , And gradually develop in the direction of integrated intelligent spinning machine, apply advanced technologies such as mechanics, electricity, hydraulics, microelectronics, light, detection, sensor technology, artificial intelligence and other advanced technologies to spinning technology, and establish a general spinning part manufacturing expert system , To be able to automatically identify product drawings and status, automatically design spinning blanks, plan manufacturing schemes, intelligently prepare process processes, and automatically optimize and adjust process parameters.

In the early days, compared with the advanced level of foreign countries, the development of spinning technology of spinning equipment in our country has certain aspects, whether in terms of product type, dimensional accuracy, spinning machine equipment capabilities and automation degree, or in process theory research. gap. However, after many scientific and technological workers are working on this research work, great development has been achieved in the past 20 years, and the accuracy and performance of many products are close to or have reached the advanced level of foreign countries. A few domestic colleges and universities, such as Harbin Institute of Technology, Beihang University, Xi'an University of Technology, etc., as well as some powerful research institutes, have been developing CNC spinning machines, conducting theoretical discussions and developing new technologies.

SAUNDERS

WRITE A MESSAGE TO US

Related products

Contact Us

Add:Wanquan industrial zone of Pingyang County Wenzhou City,Zhejiang Province

Mobile:13736707088

Tel:0577-63175265

Fax:0577-63175268

E-MAIL:okcan01@163.com

Mobile

13736707088

13736707088

Message

Message